Made in Slovakia

Made in Slovakia ISO 9001

ISO 9001 Made in Slovakia

Made in Slovakia ISO 9001

ISO 9001 Dry ice cleaning technology is becoming the standard in many areas of industry – cleaning moulds for plastic part manufacturing, cleaning moulds for tire manufacturing, casting moulds, composite moulds, or the safe cleaning of minute apertures. The removal of contaminants in this way is mostly quick and efficient. Traditional cleaning methods like manual cleaning or ultrasonic cleaning have many disadvantages that could lead to reduced productivity and increased operating costs.

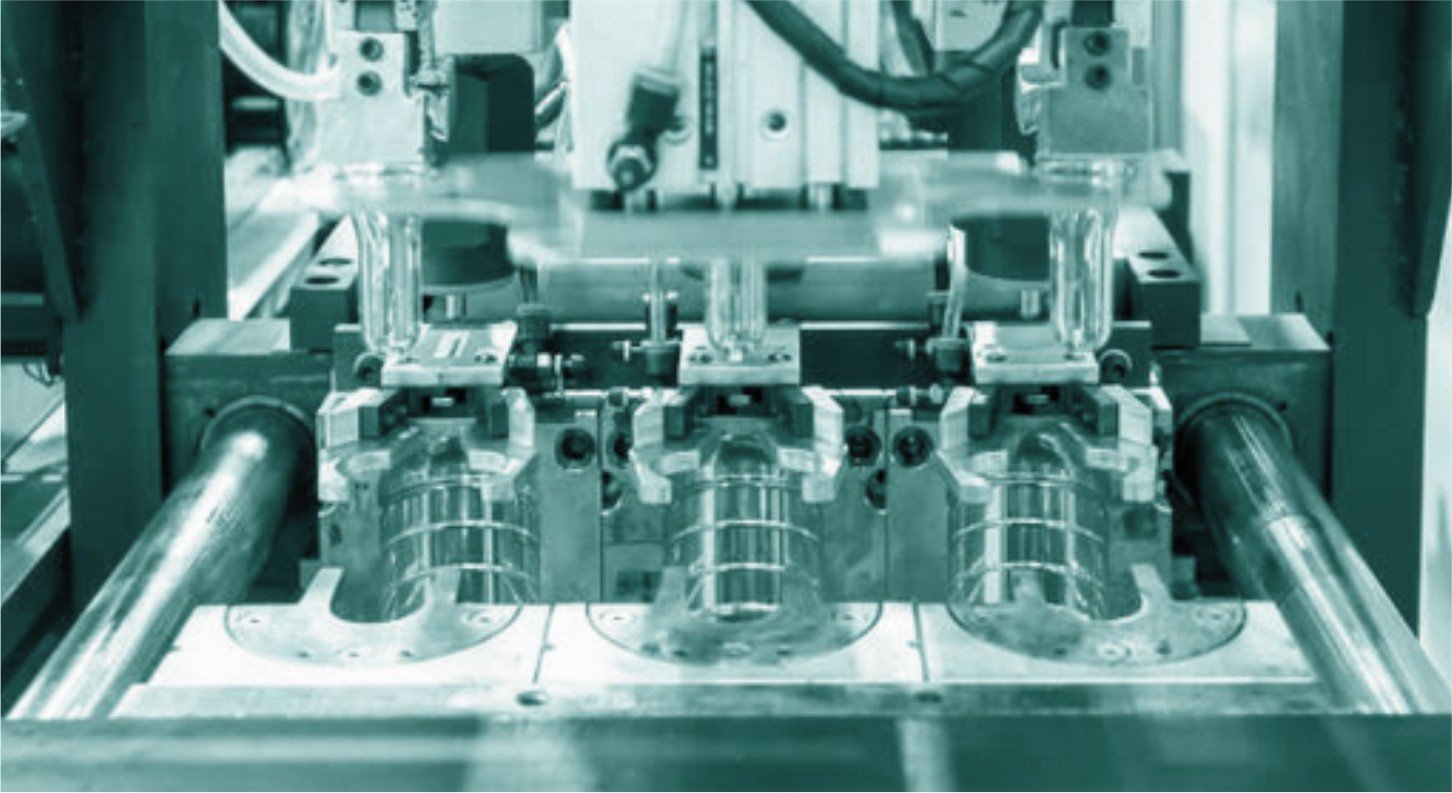

Dry ice cleaning technology is becoming the standard in many areas of industry – cleaning moulds for plastic part manufacturing, cleaning moulds for tire manufacturing, casting moulds, composite moulds, or the safe cleaning of minute apertures. The removal of contaminants in this way is mostly quick and efficient. Traditional cleaning methods like manual cleaning or ultrasonic cleaning have many disadvantages that could lead to reduced productivity and increased operating costs.Cleaning moulds and tools takes more working hours than all other phases of repair combined. This is for two reasons:

(1) Clean plates and tools are crucial to maximizing the service life and reliability of the mould, and also product quality.

(2) The vast majority of moulds are still cleaned by hand.

Manual mould cleaning is a slow and complicated process. It involves cleaning agents - sprays, solvents, and brushes – and their subsequent disposal and recycling. It requires a high-performance ventilation system, otherwise technicians may be exposed to vapours that are most likely harmful to their health. Manual cleaning methods require manipulation of the moulds to gain access from all sides. It is difficult to deal with thick rust deposits using manual cleaning.

Ultrasonic cleaning of tools and equipment is performed using solvents. An aqueous solution is usually heated, which consumes a lot of electricity and takes up significant space in the premises. In addition, ultrasonic cleaning systems require significant initial investment and have high operating costs. This makes this solution less attractive for companies with lower quantities of forms that need cleaning. The handling of mould components is limited, the technology can only be used “offline”, and generates a lot of secondary waste.

A laser cleaning system does not require any consumables, solvents, or spray cleaners. If you decide to filter dust and smoke, the filter will need replacing. Maintenance is limited to removing moisture and dust from the laser lenses. The greatest disadvantages are high initial costs, safety training, equipment, and procedures.

The ecological dry ice cleaning technology provides excellent surface finishes. Dry ice blasting is an attractive solution because it enables cleaning in situ without disassembly and cooling. Dry ice cleaning equipment uses a non-abrasive media in the form of recycled CO2, which does not damage surfaces. Dry ice can also be used to clean contaminants deposited in greater thicknesses for a long time without damaging the base material. Using this technology, it is possible to remove operating contaminants, baked-on plastics, and corrosion three times more effectively than with conventional methods.