Made in Slovakia

Made in Slovakia

ISO 9001

ISO 9001

Made in Slovakia

Made in Slovakia

ISO 9001

ISO 9001

Lives are at stake in the food industry

Bakeries, dairies, meat processors and dozens of other establishments produce thousands of tonnes of food every day, all while maintaining sanitary conditions on their production lines. Even microscopic contamination invisible to the naked eye is enough to produce tragic consequences, such as severe food poisoning, allergic reactions and other health problems. Production managers have a lot of responsibility in maintaining the cleanliness of the plant while also meeting product delivery deadlines to customers. Food poses a health risk to consumers without proper due maintenance. Delays in delivery also expose companies to the risk of high fines.

Food plant reality

It only takes a few seconds to clog machines. Dough, molasses and other raw materials can cover the production area, get into conveyor belts or packaging machines. For example, raw materials may be contaminated with nut shells and introduce undesirable allergens in food. Production residues at many plants are removed manually. Cleaning a single line may take several days – production must be shut down, production machines need to be disconnected from mains power, machines need to cool down, and sufficient qualified personnel for maintenance must be at hand. Cleaning using high-pressure water treatment creates hectolitres of liquid waste which needs to be pumped out and disposed of, creating a significant burden on the budget. Machines also need to dry before they can recommence operation, which may take a long time.

80% savings in time = one extra shift

80% savings in time = one extra shift

According to a study by the American Food Standard Agency, dry ice blasting removes a number of pathogenic microorganisms from surfaces. These microorganisms are often a cause of salmonella and listeria.

Cleaning with solid carbon dioxide pellets reduces downtime by a fifth: dry ice does not conduct electricity and is non-abrasive. Dry ice can be applied to hot surfaces and leaves no residue.

What are the benefits to you?

→ Avoid disconnecting machines and production lines from mains power or the need to dismantle machinery

→ Cleaning can begin immediately after machines are shutdown

→ Cleaned machines do not require additional disinfection

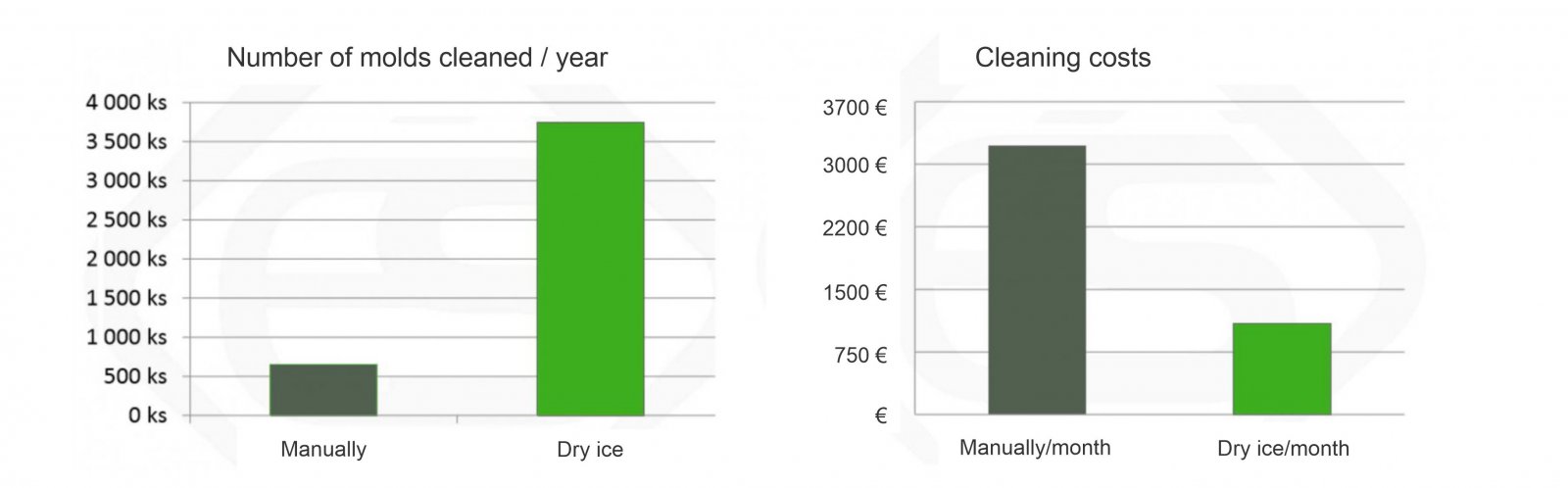

The combination of these factors means hundreds of hours saved per year – a single worker can do the same amount of cleaning with dry ice blasting equipment than an entire shift of maintenance workers with wire brushes, and several times faster.

Dry ice is also especially effective in removing fungi in locations such as breweries, bakeries and factories with conditions of high temperature and humidity.

Removal using aggressive chemistry is not compatible with hygienic principles in these operations, and other methods are simply not effective.